Slideshow -

Image 1: Photo of four types of rigid insulation

Four types of rigid insulation are fastened to a steel deck. Clockwise from upper left: EPS, mineral wool, polyurethane, and phenolic foam insulation.

Image: BDA Keuringsinstituut - Kiwa NV

Image 2: Photo of the test assembly covered by membrane roofing

The test assembly covered with a roofing membrane.

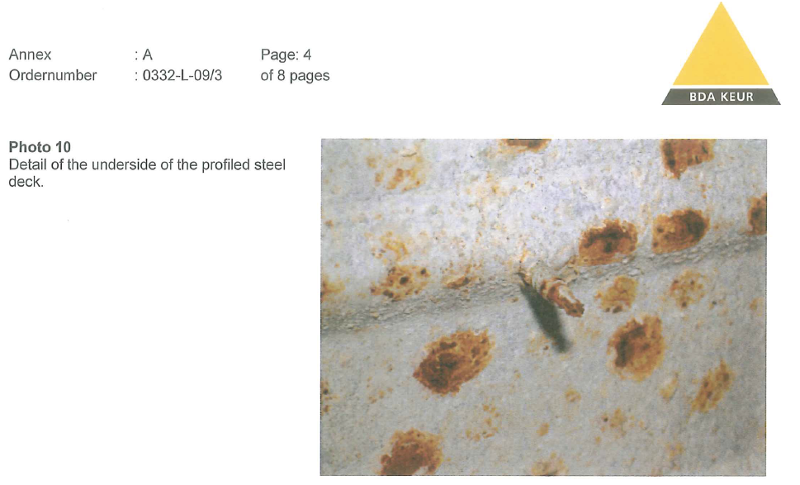

Image: BDA Keuringsinstituut - Kiwa NVImage 3: Photo of the underside of the steel deck after the test

The underside of the steel profile deck with a fastener after the test.

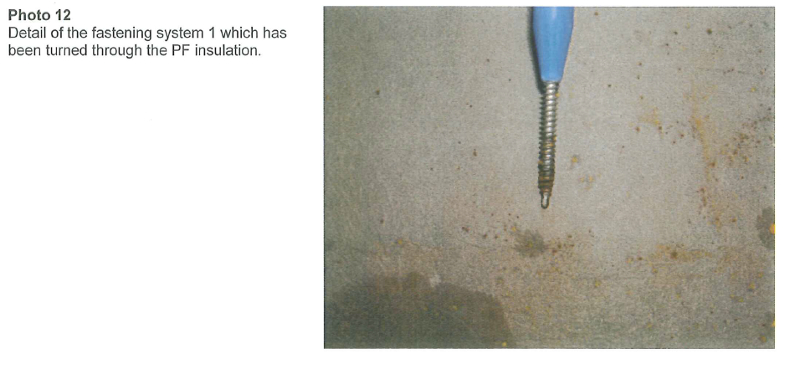

Image: BDA Keuringsinstituut - Kiwa NVImage 4: Photo of a fastener that was used for phenolic foam insulation in a test

This fastener is slightly corroded at its tip where it penetrated the roof deck, but that the portion of the fastener in sustained contact with the 2 inches of phenolic foam insulation is not corroded.

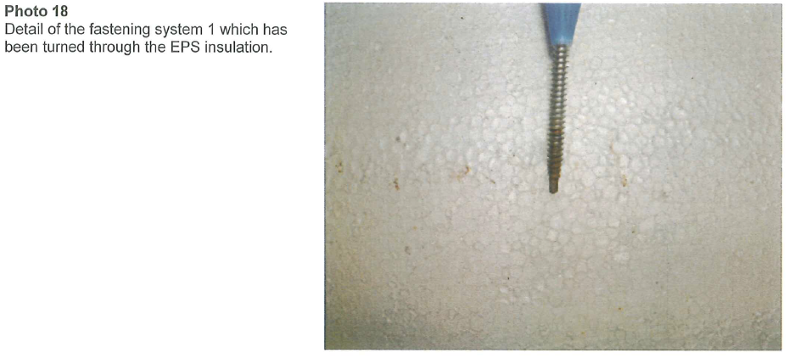

Image: BDA Keuringsinstituut - Kiwa NVImage 5: Photo of a fastener that was used for EPS insulation in a test

The corrosion pattern for this fastener in the EPS insulation is very similar to the fastener in Image 4 (in the phenolic foam insulation).

Image: BDA Keuringsinstituut - Kiwa NVImage 6: Photo of a fastener used to hold Kingspan insulation in Brattleboro VT

From the attic with two layers of Kingspan Kooltherm phenolic foam insulation, a fastener has been backed part way out.

Photo: Peter YostImage 7: Photo of a screw entirely removed from the insulation at the Brattleboro job

This is the same fastener that was shown in Image #6. The screw has been backed out all the way to show that there is no corrosion anywhere on the fastener. That's no big surprise, given that it is a baked enamel fastener that was only installed a few months ago.

Photo: Peter YostImage 8: Photo of a wall mockup that was stored in a damp garage

This wall mockup from the same project as the insulation job discussed in my previous blog (81 Chapin Street, Brattleboro, Vermont) was stored for several months in my garage, which tends to be quite damp because the garage slab is old, broken, and has no moisture barrier between it and the soil underneath the garage

Photo: Peter YostImage 9: Photo of a drywall screw used in the wall mockup

A screw — a drywall screw intended for interior use, not galvanized or otherwise treated — from the wall mockup, showing no corrosion along its length.

Photo: Peter YostImage 10: Photo showing a screw reinstalled in a moistened screw hole

I backed out a couple of screws, dumped water into the fastener holes, and then reinstalled the screws.

Photo: Peter YostImage 11: Photo of a screw removed after a week spent in a damp screw hole

A week later, there was still no corrosion on the drywall screw

Photo: Peter YostImage 12: Photo of a PowerPoint slide by Dr Jan Kosny

The title slide of a PowerPoint presentation by Dr. Jan Kosny of the Fraunhofer Institute: “Development of a Bio-based, Inexpensive, Noncorrosive, and Nonflammable Phenolic Foam for Building Insulation.”

Image: Fraunhofer Institute U.S.A.Image 13: Photo of rooftop corrosion testing by Fraunhofer Institute

The rooftop of the test hut where 8 different types of phenolic foam rigid insulation underwent a corrosion test

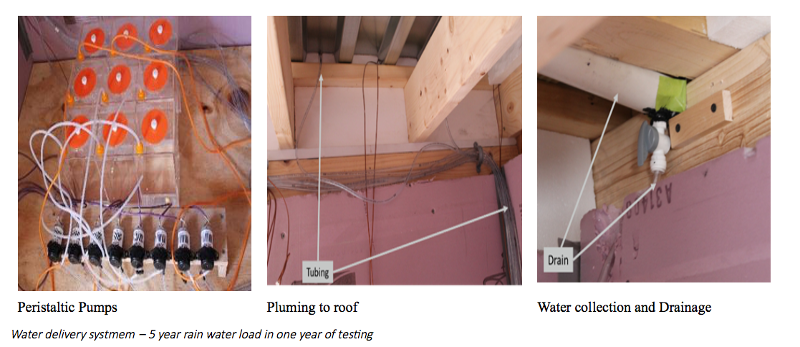

Image: Fraunhofer Institute U.S.A.Image 14: Photo showing moisture delivery system used in the test hut

These photos show the inside of the Fraunhofer rooftop test hut and show how water is delivered to the roof system to load the installed phenolic foam rigid insulation with moisture.

Image: Fraunhofer Institute U.S.A.